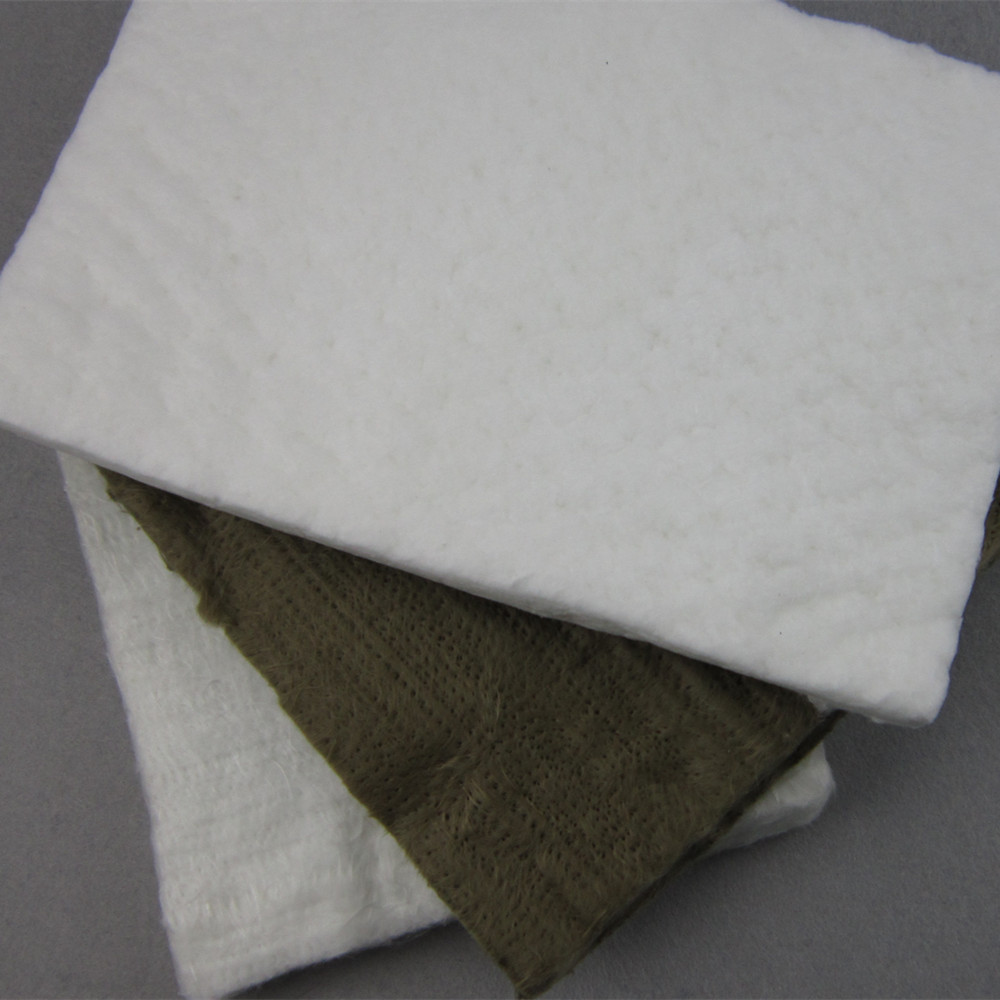

Materialbasis : Reine amorphe Kieselsäurefasern (≥96 % SiO₂-Gehalt), verarbeitet zu einer dichten, nadeligen Struktur.

Thermische Leistung :

Dauereinsatz : 1000 °C (1832°F), mit kurzfristiger Toleranz bis zu 1260 °C (2300 °F).

Minimale lineare Schrumpfung (<2 %) bei 1000 °C, wodurch langfristige Dimensionsstabilität gewährleistet wird.

Hauptvorteile :

Chemisch inert: Beständig gegen Säuren, Laugen und Oxidation, auch bei extremer Hitze.

Ultra-niedrige Wärmeleitfähigkeit ( 0,035–0,045 W/m·K ) für hervorragende Wärmespeicherung.

Nicht brennbar (Brandschutzklasse A) und keine flüchtigen Emissionen.

Typische Anwendungsfälle :

Hochtemperatur-Auspuffkomponenten (Turbolader, Fächerkrümmer, Rennauspuffanlagen).

Kritische Wärmeabschirmung in der Luft- und Raumfahrt, in Gießereien und der Energieerzeugung.

Materialbasis : E-Glasfasern (Calcium-Aluminoborosilikatglas) zu einer flexiblen Matte verbunden.

Thermische Leistung :

Dauereinsatz : 450–550 °C (842–1022°F), wobei einige modifizierte Sorten eine kurze Exposition gegenüber 700°C (1292 °F).

Hauptvorteile :

Kosteneffizient: ~50–70 % günstiger als Lösungen auf Siliziumbasis.

Hervorragende Schallabsorption (NRC 0,65–0,85) zur Geräuschreduzierung in Abgassystemen.

Lässt sich leicht schneiden und an unregelmäßige Oberflächen anpassen (Dichte: 60–100 kg/m³).

Einschränkungen :

Allmähliche Faserversprödung über 500 °C, wodurch die Gefahr der Partikelfreisetzung besteht.

Mögliche Freisetzung von Formaldehyd in feuchten, sehr heißen Umgebungen (erfordert UL GREENGUARD-Zertifizierung).

| Parameter | Silica-Nadelmatte | Fiberglas-Nadelmatte |

|---|---|---|

| Spitzentemperatur | 1260 °C (2300 °F) | 700°C (1292°F) kurzzeitig |

| Wärmeleitfähigkeit | 0,035–0,045 W/m·K | 0,05–0,08 W/m·K |

| Chemische Beständigkeit | Außergewöhnlich (pH 1–14 stabil) | Mäßig (zersetzt sich in starken Säuren) |

| Akustische Dämpfung | Begrenzt (NRC 0,3–0,4) | Hoch (NRC 0,7–0,85) |

| Lebensdauer bei 600°C | 10+ Jahre | 2–5 Jahre |

Turbolader-/Diesel-Auspuffanlagen :

Verwenden Sie Silicamatten in der Nähe von Turbos/DPFs, wo die Gastemperatur 800 °C übersteigt.

Fiberglas eignet sich für Auspuffendrohre/Schalldämpfer (<500 °C).

Gewichtssensitive Designs :

Kieselsäure: Höhere Kosten, aber 30 % leichter als Alternativen aus Keramikfasern.

Fiberglas: Kostengünstig für nicht kritische Wärmezonen.