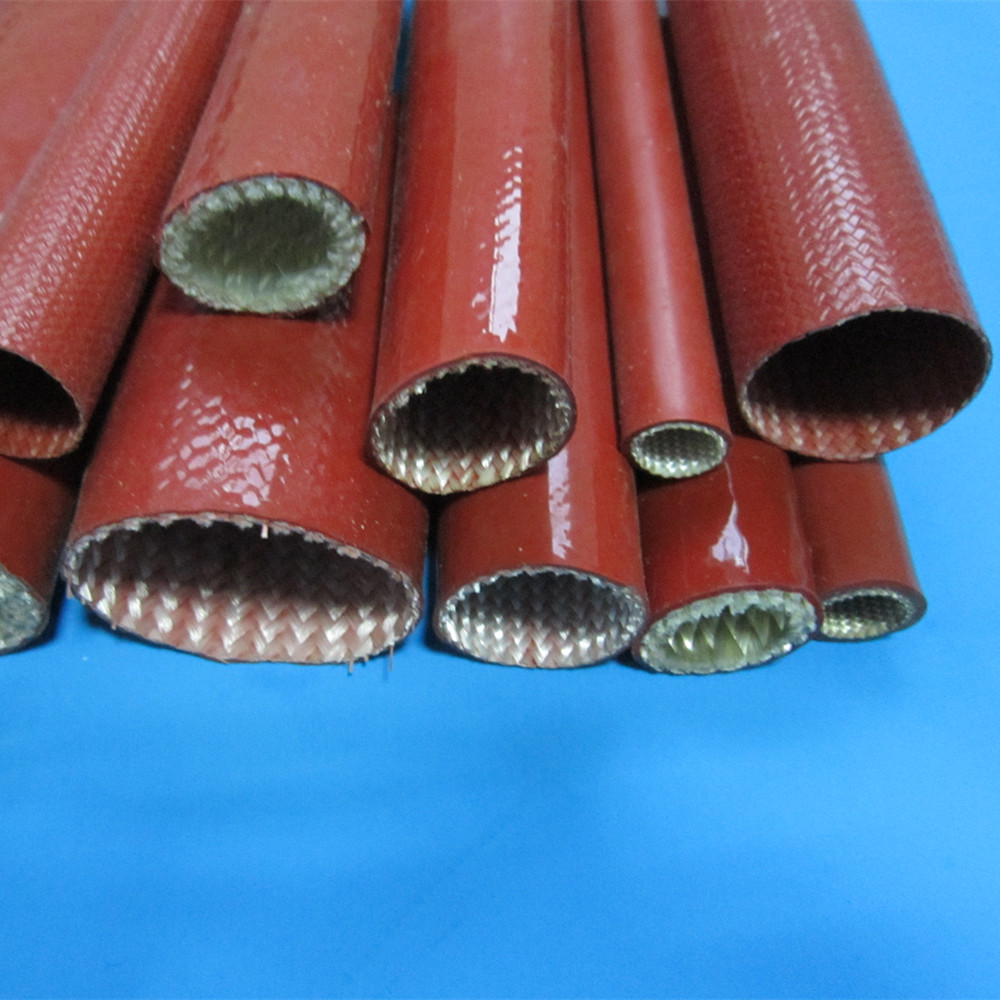

Silikonbeschichteter Glasfaserschlauch ist eine unverzichtbare Isolierlösung für Hochleistungsanwendungen, die für hohe elektrische, thermische und mechanische Anforderungen ausgelegt ist. Dieser Schlauch eignet sich ideal für die Isolationsklassen B (130 °C), F (155 °C) und H (200 °C) und ist so konstruiert, dass er extremen Temperaturen standhält und gleichzeitig überragende Flexibilität und Haltbarkeit bietet. Mit seiner hervorragenden Rückstoß- und Durchschneidefestigkeit funktioniert es effektiv in rauen Umgebungen, in denen Zuverlässigkeit von größter Bedeutung ist.

Darüber hinaus bietet der Schlauch einen robusten mechanischen Schutz und ist abriebfest, sodass er sich perfekt für den Langzeiteinsatz in einer Vielzahl elektrischer und mechanischer Anwendungen eignet.

Silikonbeschichtete Glasfaserschläuche sind vielseitig und können in einer Vielzahl von Branchen eingesetzt werden, darunter:

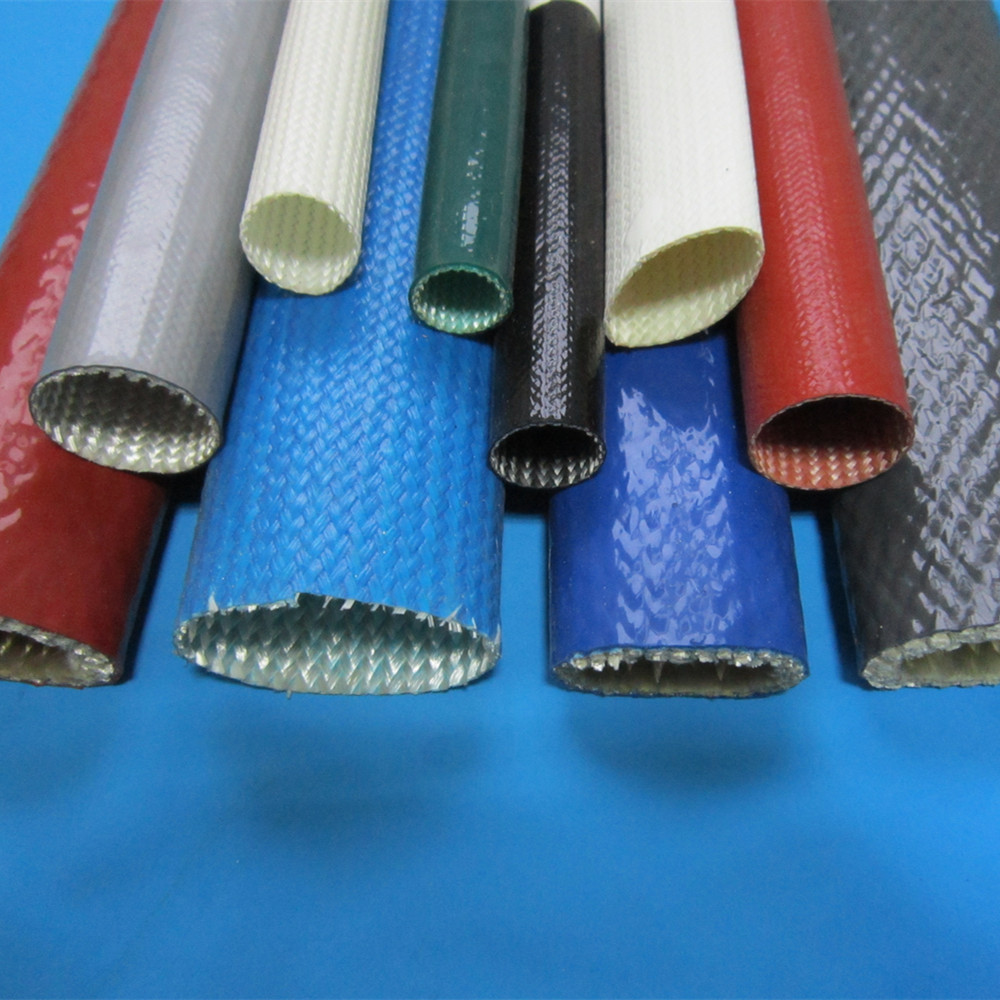

Neben silikonbeschichteten Schläuchen bieten wir auch unbeschichtete und harzgetränkte Glasfaserschläuche für Anwendungen an, die die Isolationsklasse C (über 240 °C) erfordern. Diese Optionen bieten sowohl in geflochtener als auch in gestrickter Ausführung einen hochtemperaturbeständigen, ausfransfesten Schutz und erweitern so die Palette der verfügbaren Lösungen für anspruchsvolle Anforderungen an die elektrische Isolierung.

Ganz gleich, ob Sie Stromversorgungssysteme isolieren, Motorspulen schützen oder empfindliche Komponenten abschirmen möchten – silikonbeschichtete Glasfaserschläuche bieten die Festigkeit, Flexibilität und den Schutz, die für eine Vielzahl von Hochleistungsanwendungen erforderlich sind.