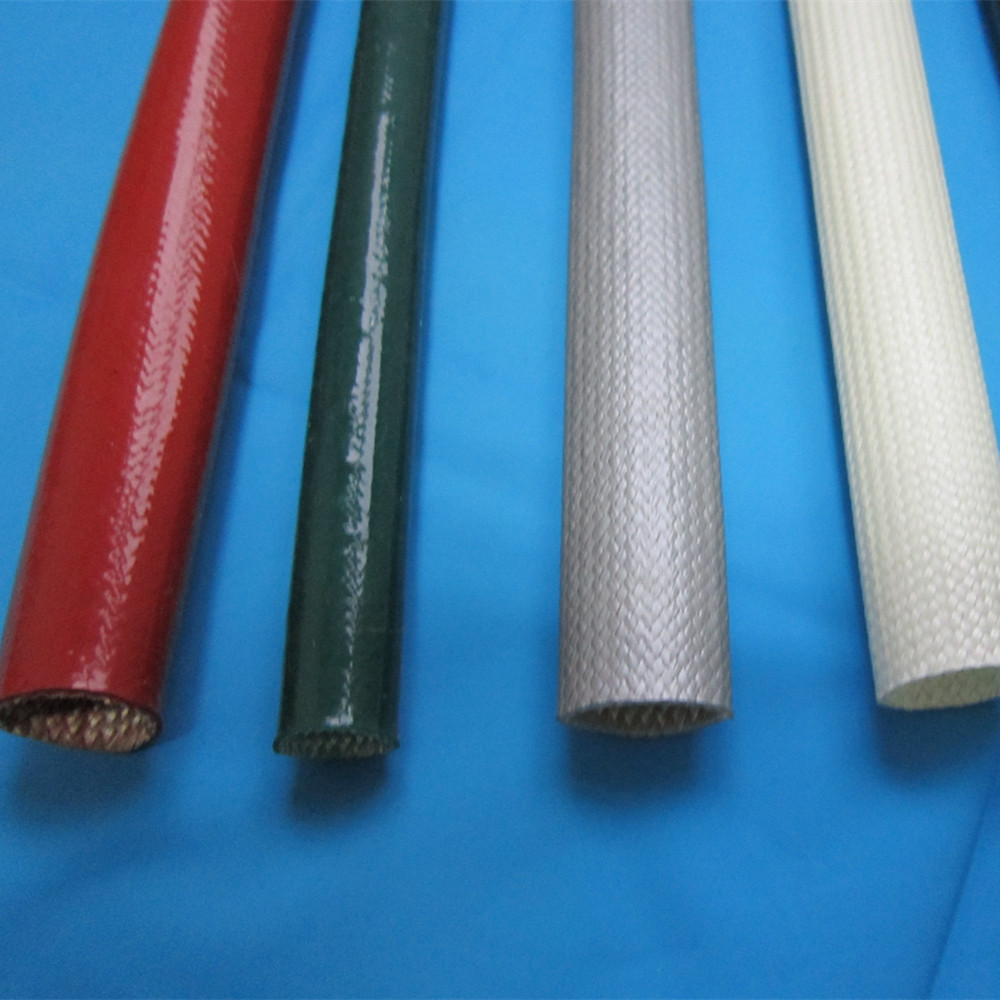

Mit Silikon beschichtete Glasfaserhülse ist eine sehr vielseitige und langlebige Schutzlösung, die eine außergewöhnliche Isolierung und Resistenz gegen hohe Temperaturen bietet Diese Ärmel kombiniert die Stärke und Flexibilität von Glasfaser mit den hitzebeständigen Eigenschaften von Silikon und ist ideal für eine Vielzahl von Anwendungen in verschiedenen Branchen Es gewährleistet einen optimalen Schutz für Drähte, Kabel und Schläuche in anspruchsvollen Umgebungen und bietet eine lang anhaltende Leistung und Zuverlässigkeit

Schlüsselmerkmale:

Branchenanwendungen:

Automobilindustrie: Silikonbeschichtete Glasfaserärmel wird üblicherweise in Automobilverdrahtung, Schläuchen und Kabeln verwendet, um sie vor extremen Temperaturen, Öl und Abrieb zu schützen Sein hoher Wärmewiderstand sorgt für die Langlebigkeit und Zuverlässigkeit von elektrischen Systemen und Kraftstoffleitungen

Luft- und Raumfahrtindustrie: Die Luft- und Raumfahrtindustrie benötigt Materialien, die extremen Bedingungen standhalten können, einschließlich hoher Temperaturen und mechanischer Belastungen Silikon beschichtete Glasfaserhülsen werden zum Schutz von Flugzeugkabeln, Kraftstoffleitungen und hydraulischen Schläuchen in rauen Umgebungen verwendet

Meeresindustrie: In der Meeresindustrie wird mit Silikon beschichteten Glasfaserhülsen zum Schutz von Kabeln, Verkabelung und Schläuchen in Motorräumen und anderen Hochhitzebieten verwendet Es stellt sicher, dass die Systeme auch in harten marinen Umgebungen reibungslos funktionieren, wo die Exposition gegenüber Salzwasser, hohen Temperaturen und mechanischer Verschleiß häufig vorkommt

Öl- und Gasindustrie: Silikon beschichtete Glasfaserhülsen sind im Öl- und Gassektor für den Schutz von Kabeln, Kabeln und Schläuchen, die hohen Temperaturen, Chemikalien und mechanischen Verschleiß ausgesetzt sind, von wesentlicher Bedeutung Es hilft, Ausfälle in kritischen Systemen und Geräten zu verhindern, die beim Bohren, Raffinieren und Transportmittel eingesetzt werden

Stromerzeugung: In Kraftwerken und Energieanlagen wird dieser Ärmel zum Schutz von Kabeln, Kabel und Schläuchen verwendet, die hohen Temperaturen vor Dampf, Auspuff und heißen Geräten ausgesetzt sind Die hervorragenden Isolationseigenschaften tragen dazu bei, sichere und effiziente Stromerzeugungssysteme aufrechtzuerhalten

Industrielle Fertigung: Silikonbeschichtete Glasfaserhülsen werden in Industrie -Produktionsumgebungen häufig verwendet, um Maschinenkabel, Schläuche und Ausrüstung vor Hitze, Abrieb und chemischer Exposition zu schützen Es hilft, die fortgesetzte Leistung von Produktionssystemen unter extremen Bedingungen zu gewährleisten

Brandschutz: Silikonbeschichtete Glasfaserhülsen werden in Brandschutzanwendungen verwendet, um Feueralarmkabel, Kabel des Sprinklersystems und elektrische Komponenten, die potenziellen Brandgefahren ausgesetzt sind, isolieren Seine flammresistenten Eigenschaften tragen dazu bei, das Risiko von elektrischen Bränden in kritischen Systemen zu verringern

Bauindustrie: Die Bauindustrie nutzt diese Ärmel, um elektrische Kabel- und Rohrleitungssysteme in hochheizigen Anwendungen wie Kessel, Heizsystemen und HLK-Einheiten zu isolieren und zu schützen Es hilft bei der Aufrechterhaltung der Systemeffizienz und verhindert elektrische Fehler

Abschluss: Mit Silikon beschichtete Glasfaserhülse ist ein wesentliches Material, um einen überlegenen Schutz in Branchen zu gewährleisten, das Wärme, Flamme, Abrieb und chemische Resistenz benötigt Seine Haltbarkeit, Flexibilität und hervorragende thermische Isolationseigenschaften sind ideal für Automobil-, Luft- und Raumfahrt-, Meeres-, Öl- und Gas-, Stromerzeugungs-, Industrie- und Brandschutzanwendungen Egal, ob Sie Kabel, Kabel oder Schläuche unter extremen Bedingungen isolieren, dieser Ärmel bietet eine lang anhaltende, zuverlässige Leistung in einer Vielzahl von anspruchsvollen Umgebungen.